H.E.L Group Process Safety and Scale-Up

Asia Mattelab is the distributor for H.E.L Group Battery Testing Calorimeter in Singapore and South East Asia (Malaysia, Thailand, Vietnam, Indonesia, Philippines).

H.E.L Group has a long history of solving complex challenges for customers. Since 1987, the Company has worked with businesses and laboratories globally, providing proprietary automated solutions for the pharma, biotechnology, chemical, battery, and petrochemical sectors.

In industries ranging from pharmaceuticals to fine chemicals, scaling-up bench-top chemical reactions to production volumes carries a number of risks and challenges.

H.E.L Group has a long history of solving complex challenges for customers. Since 1987, the Company has worked with businesses and laboratories globally, providing proprietary automated solutions for the pharma, biotechnology, chemical, battery, and petrochemical sectors.

In industries ranging from pharmaceuticals to fine chemicals, scaling-up bench-top chemical reactions to production volumes carries a number of risks and challenges.

Central to the risks involved with scale-up are the changes in heat loss behavior with scale:

- Many reactions are exothermic and require cooling to ensure safe operation when performed on a large scale;

- Components in the reaction may become unstable under certain operating conditions, leading to additional thermal hazards.

- Identifying and mitigating risk sources during the process scale-up is necessary.

H.E.L Group has a range of solutions to help you identify and quantify thermal hazards at the laboratory scale, which support your process safety and scale-up requirements.

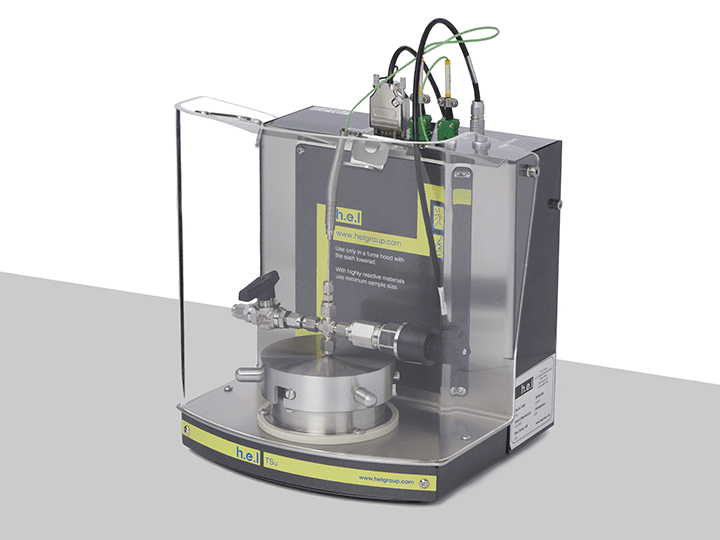

TSu | Thermal and Pressure Hazard Screening Platform

The fast screening of thermal hazards can be performed with the Thermal Screening Unit (TSu). It uses samples typical from 0.5 to 5g, will generate both temperature pressure data, and hence can be considered a better alternative to classical DSC/DTA methods.

The TSu typically finds application in:

- Thermal reaction screening of reaction hazards in process scale-up

- thermal stability studies on the reaction waste stream

This is due to its ability to characterize sample pressure changes in addition to thermal behavior, and its capability in supporting relatively large sample measurements.

For effective reaction hazard screening, two critical pieces of data are needed:

- the onset temperature (Td) of the reaction- where the exotherm is detected

- the pressure generated by the resultant runaway

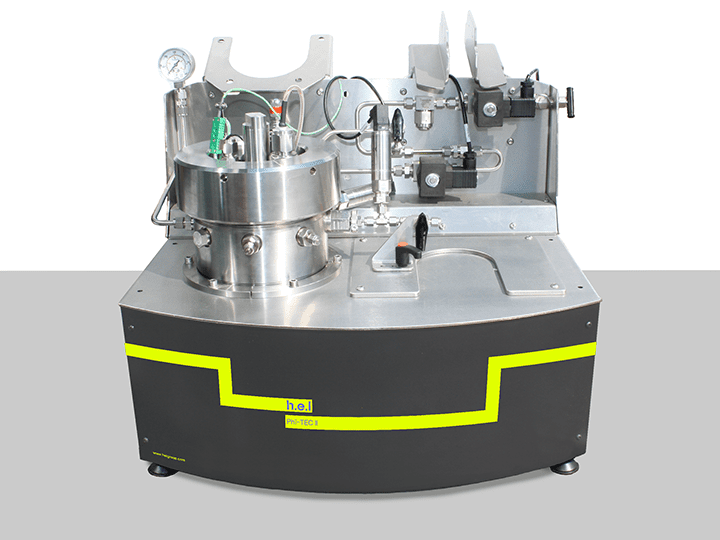

Phi-TEC I | Bench-top, high phi-factor, adiabatic calorimeter

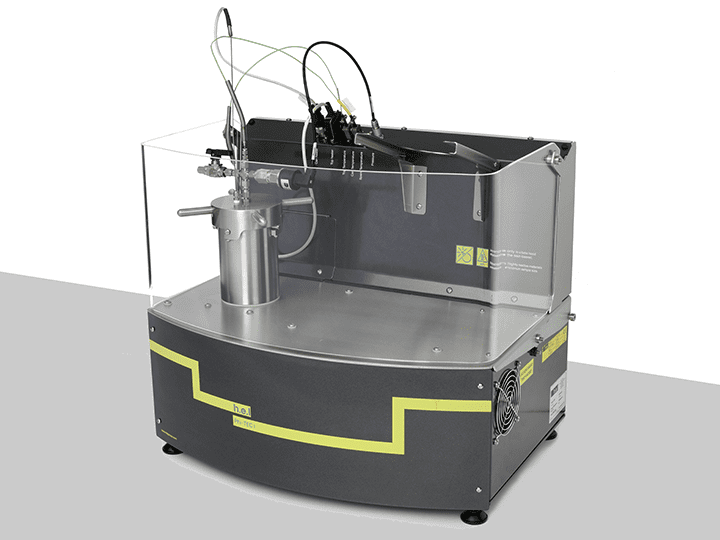

Phi-TEC II | Bench-top, low phi-factor, adiabatic calorimeter

Simular | Process Development Reaction Calorimeter