Industrial Drying Oven

An industrial drying oven is a large-scale oven specifically designed for industrial applications that require drying, curing, or heat treatment processes on a larger or bulkier scale. These ovens are used in various industries, such as manufacturing, food processing, pharmaceuticals, electronics, automotive, and more. Industrial drying ovens are known for their robust construction, higher capacities, and advanced features to meet the demanding requirements of industrial production environments.

Here are some key features and considerations related to industrial drying ovens:

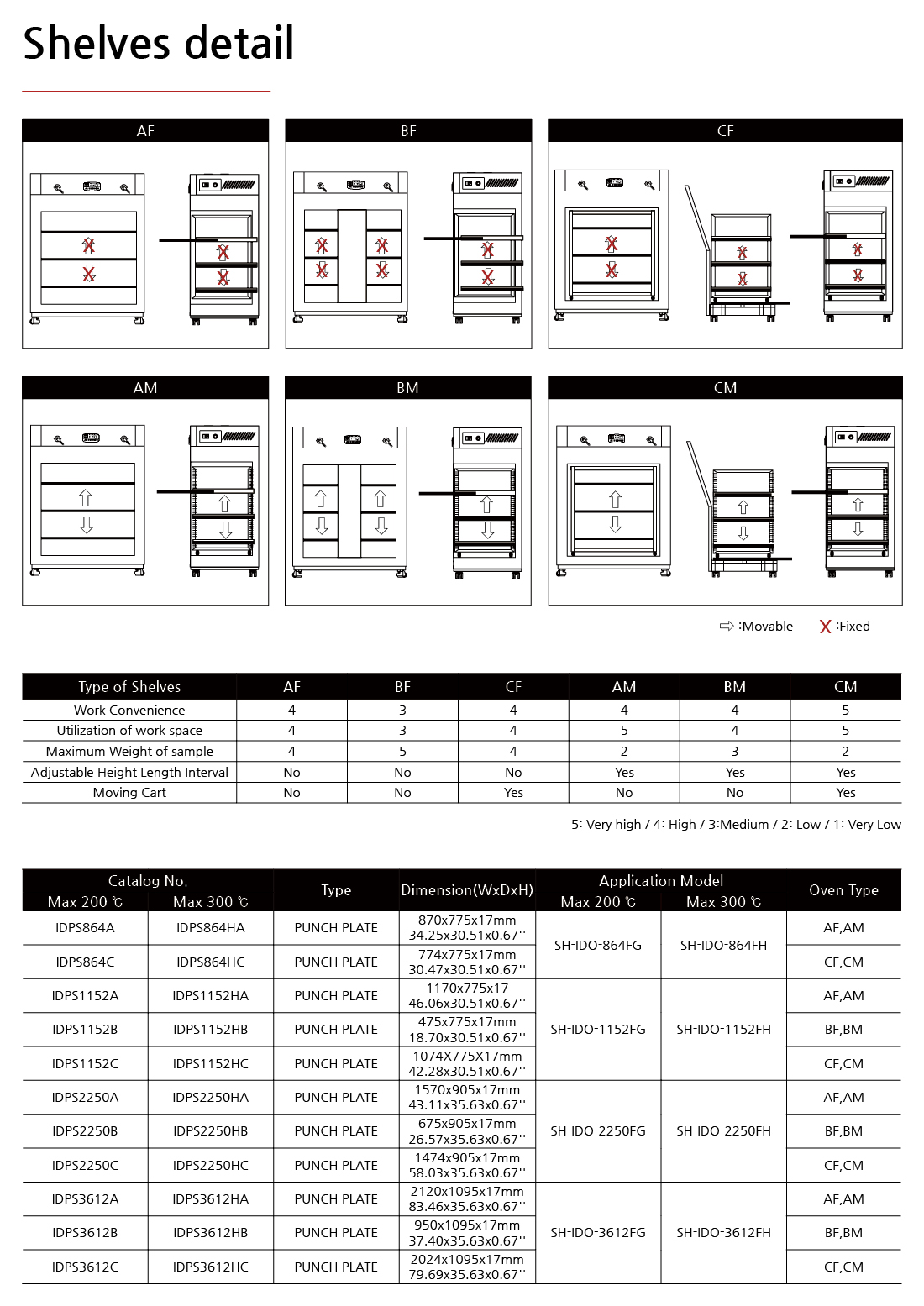

Size and Capacity: Industrial drying ovens are typically larger in size compared to laboratory or smaller-scale ovens. They come in various sizes and configurations to accommodate larger volumes of materials or bigger components. The capacity of an industrial drying oven can range from a few cubic feet to several thousand cubic feet, depending on the application.

Temperature Range: Industrial drying ovens offer a wide temperature range to accommodate different drying or heat treatment requirements. They can typically achieve and maintain temperatures ranging from ambient temperatures to several hundred degrees Celsius, depending on the specific model and application.

Construction and Insulation: Industrial drying ovens are built with sturdy materials such as stainless steel or heavy-gauge steel to withstand the demands of industrial environments. They often feature robust insulation to minimize heat loss and improve energy efficiency. Insulation materials can include ceramic fiber, mineral wool, or high-temperature insulation materials.

Heating System: These ovens utilize powerful heating systems to generate and distribute heat within the oven chamber. Common heating methods include electric heating elements, gas burners, or infrared heating systems, depending on the specific application and requirements.

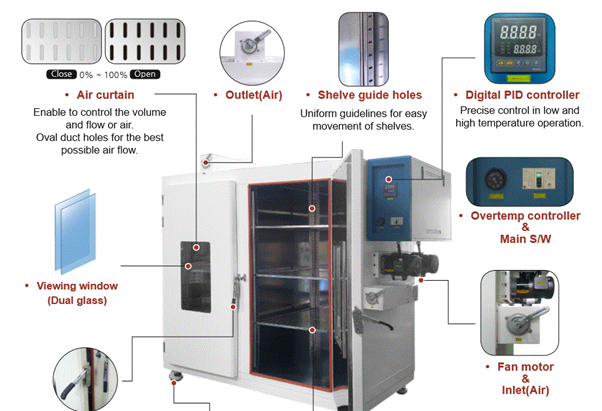

Air Circulation: Industrial drying ovens employ forced convection or recirculation systems to ensure uniform heat distribution and efficient drying. They may include powerful fans or blowers to facilitate airflow and improve heat transfer, ensuring consistent drying across the entire oven chamber.

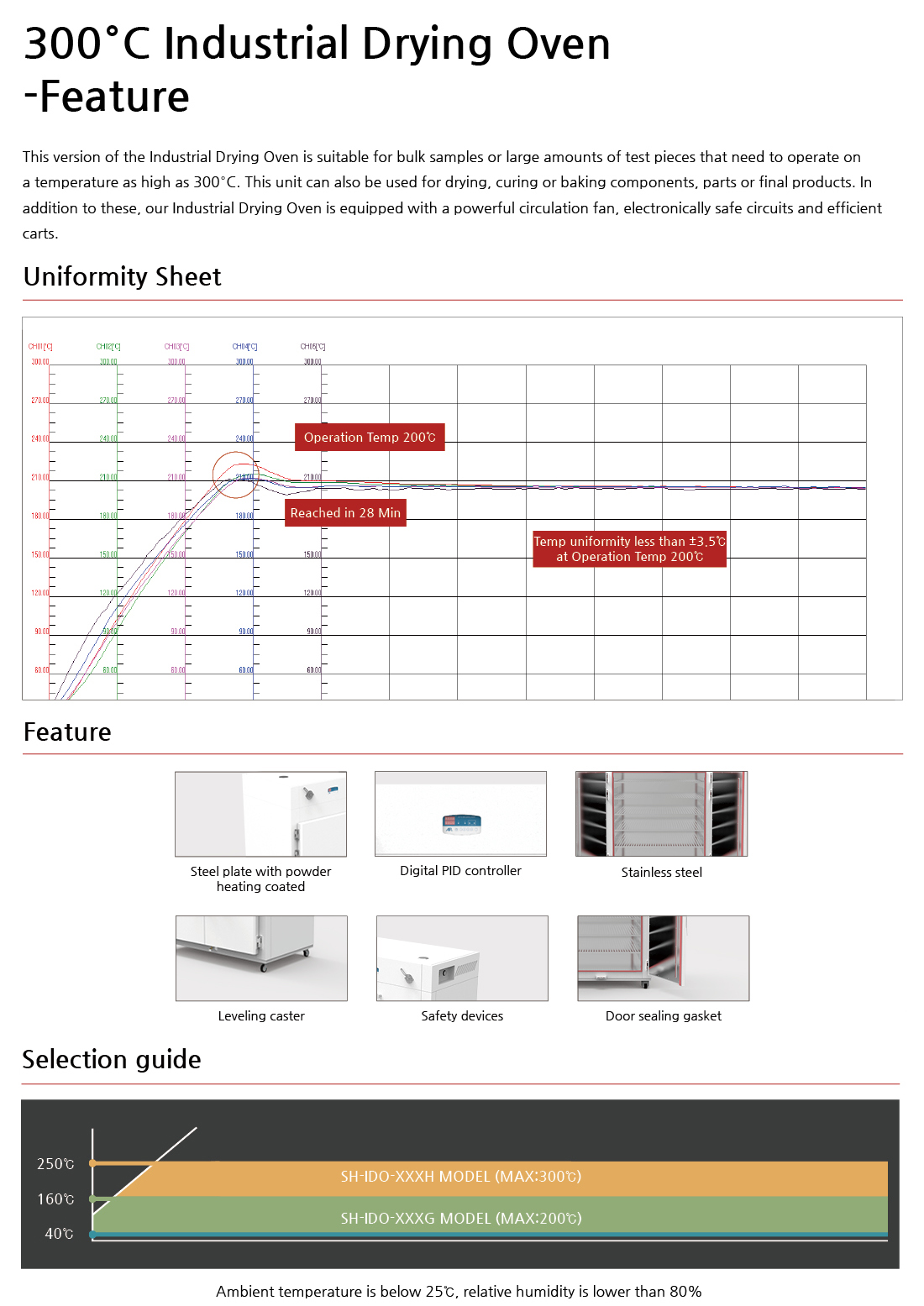

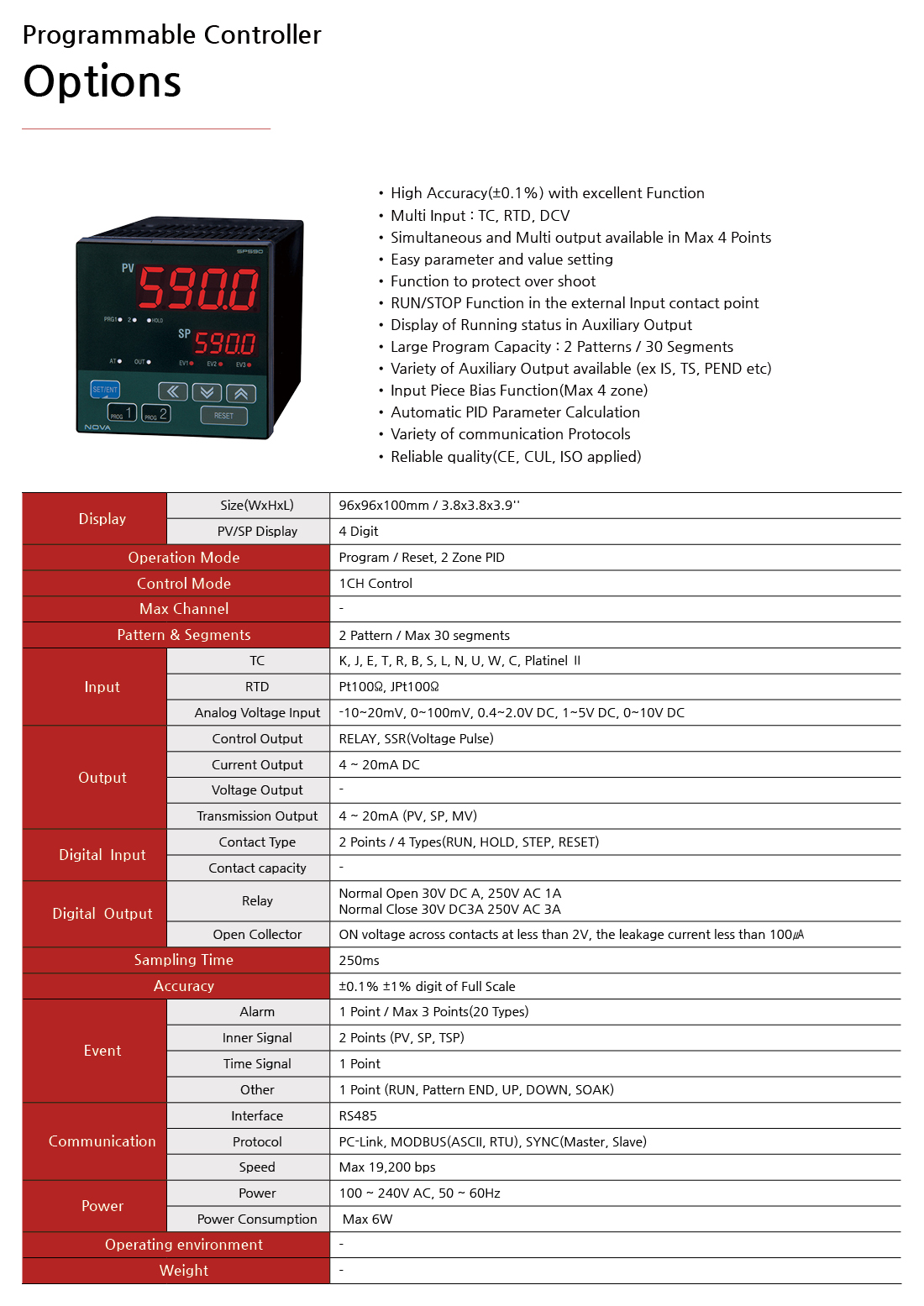

Temperature Control and Monitoring: Industrial drying ovens feature advanced temperature control systems to accurately regulate and maintain the desired temperature. These can include digital temperature controllers, programmable controllers, or computerized control systems. Additionally, they may have temperature monitoring capabilities for data logging or process control purposes.

Safety Features: Industrial drying ovens incorporate various safety features, such as over-temperature protection, safety interlocks, and alarm systems. These features help to ensure operator safety and prevent potential hazards or equipment damage.

Customization and Integration: Industrial drying ovens can be customized to suit specific process requirements, such as incorporating conveyor systems for continuous drying, integrating PLC (Programmable Logic Controller) for automation, or adapting to specific material handling needs.

Compliance and Certifications: Industrial drying ovens may adhere to industry standards and certifications, depending on the application or industry. These certifications can include ISO, CE, UL, or other relevant standards to ensure compliance with safety and quality regulations.

Industrial drying ovens are essential for large-scale drying or heat treatment processes in various industrial sectors. Their robust construction, high capacity, advanced features, and customization options make them suitable for demanding industrial applications where consistent and efficient drying is required.

300°C Industrial Drying Oven

A 300°C industrial drying oven is a specific type of industrial oven designed to operate at temperatures up to 300 degrees Celsius. These ovens are commonly used in industrial applications where materials or products require drying, curing, or heat treatment at elevated temperatures.

Here are some key features and considerations related to a 300°C industrial drying oven:

Temperature Range: A 300°C industrial drying oven can reach and maintain temperatures up to 300 degrees Celsius (or 572 degrees Fahrenheit). The ability to achieve and sustain high temperatures makes it suitable for applications that involve drying or heat treatment of materials that require elevated temperatures.

Construction: Industrial drying ovens are constructed with sturdy materials to withstand the demands of industrial environments. The oven chamber is typically made of stainless steel or heavy-gauge steel, which provides durability and resistance to high temperatures.

Heating System: These ovens utilize powerful heating systems to generate and distribute heat within the oven chamber. Common heating methods include electric heating elements, gas burners, or infrared heating systems. The heating system is designed to provide efficient and uniform heat transfer for optimal drying results.

Temperature Control: A 300°C industrial drying oven is equipped with a temperature control system to accurately regulate and maintain the desired temperature. Advanced temperature controllers, programmable controllers, or computerized control systems may be used to ensure precise temperature control.

Air Circulation: Industrial drying ovens employ forced convection or recirculation systems to ensure uniform heat distribution and efficient drying. They may include powerful fans or blowers to facilitate airflow and improve heat transfer, ensuring consistent drying across the entire oven chamber.

Safety Features: Industrial drying ovens incorporate various safety features to ensure operator safety and prevent potential hazards. These features can include over-temperature protection, safety interlocks, door locks, and alarms.

Capacity: Industrial drying ovens come in various sizes and configurations to accommodate different production requirements. The capacity of an industrial drying oven can range from smaller units suitable for laboratory-scale operations to large-scale ovens capable of handling bulk quantities or larger components.

Applications: A 300°C industrial drying oven finds application in various industries, including manufacturing, electronics, automotive, aerospace, and more. It can be used for drying coatings, curing adhesives, heat treatment of metal parts, or any process that requires controlled and elevated temperatures.