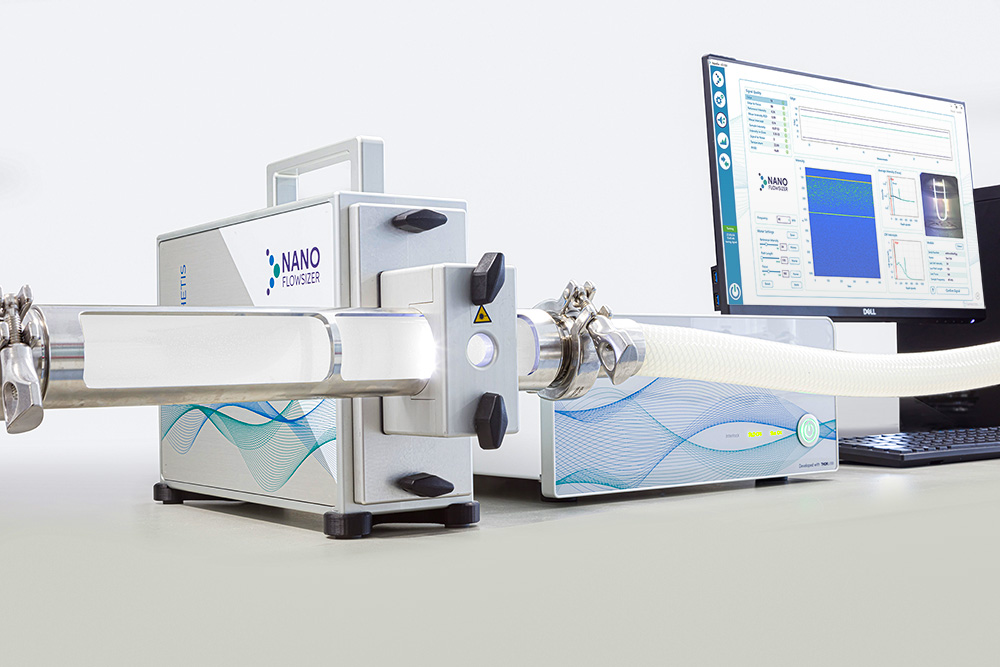

InProcess-LSP - NanoFlowSizer

Being experts in nanoparticle size characterization, they are the inventors of the NanoFlowSizer: a unique, non-invasive nanoparticle size instrumentation for real-time measurement. The NanoFlowSizer offers unique properties and is the only instrument capable of measuring particle size and size distribution of turbid nanosuspensions in flow, without the need for sample treatment or dilution. (see InProcess-LSP)

InProcess-LSP, NanoFlowSizer

The ONLY TRUE inline Nanoparticle Analyzer in the Market today. Nanoparticles could be natural or synthetic particles by nature with a size 1-1,000 nm. Due to their ultra-small size they have a large surface area in relation to their volume, providing them with special properties. Nanoparticles are present in many of the items in our everyday life, such as sunscreens, medicines, inks etc.. Of special interest within the pharmaceutical industry, nanoparticles could be used in different formulations, such as drug delivery systems for transporting systems through the body. (Visit NanoFlowSizer)

To overcome the limitations of conventional DLS for process analytical applications InProcess-LSP developed a new innovative technology: Spatially Resolved Dynamic Light Scattering (SRDLS). SR-DLS allows particle size characterization in process flows and can measure highly turbid suspensions without dilution. (See NFS technology)

Unique benefits of SR-DLS

- Analysis of highly turbid suspensions

- Measurement in flow

- Sample preparation not necessary

- Real-time process control

- Monitoring of continuous manufacturing possible

- Continuous size characterization of nanoparticles during processing

- Inline Process Analytical Tool

- Non-invasive measurement

- Real-time process feedback

- Measurement of highly turbid materials High-speed measurement Inline, online and offline operation

- For very small (<<mL) to large sample volumes

Roadmap to your process control

InProcess-LSP recognizes the importance of delivering not only innovative instrumentation but assure adequate performance and optimal alignment with customer objectives. Therefore, a step-wise implementation approach is recommended between initial feasibility screening and final implementation of the technology for new applications. Our NanoFlowSizer solution concept includes the implementation of the instrument equipped with the right process connectors meeting your (process) requirements. (Visit InProcess-LSP)

Nano-Emulsions – with inline processing, the droplet size can be monitored in real time and thus the process variables can be modified accordingly to obtain the desirable droplet size.

- Measure emulsions created using high pressure homogenisation in food and pharma industries.

- Measure particle (droplet) size of a lipid nano-emulsion formulation with propofol (anesthetic for Covid-19 intensive care patients).

- Combine with other technologies like an NIR probe for particle size plus chemical composition in solution in real time.

- Inline size monitoring of liposomes at different scales (from microliter to liter), using a variety of modules.

- local behavior of the liposomes, such as interactions with the wall, can be tracked.

- Local dynamics and local size phenomena, e.g. depletion, and segregation, that standard DLS can not observe.

- Inline measurement of nanoparticle formulations can be used in either development laboratories, pilot plants or commercial operations.

- Production processes of vaccines get direct real time feedback about quality, purity and particle size every 10 seconds.

- Enables continuous nanomedicine manufacturing with the benefit of high quality, high efficiency and lower costs.

- Silica, Iron, Titanium dioxide, Gold particles

- Polymers, Inks, Coatings