NanoGenizer Laboratory-scale High Pressure Homogenizer, "Plug & Play" Unit

The NanoGenizer-30K from Genizer is an electric benchtop, laboratory-scale, high-pressure homogenizer, which has been developed specifically for bacterial and cell lysis (such as yeasts and E. coli). It aids laboratory research and development and small-scale production at ultra-high pressure (maximum pressure up to 45,000 psi/3,000 bar), and there is no requirement for hydraulic oil or compressed air. It is available in both the 3D-printing and stainless versions.

Minimum sample volume: 5 ml

- Precision sampling as accurate as 0.1ml resolution

- Touch screen, PLC control panel

- Application: Nano emulsions, liposomes, fat emulsions, nano dispersion, cell disruption, deagglomeration, graphene, and carbon nanotube

The NanoGenizer features a microfluidics Diamond Interaction Chamber with nano-size microchannels inside the chamber where your formulation is subjected to forces of high shear and strong impact and result in nano particle dispersion and nano cell disruption. Using the Diamond Interaction Chamber technology, the NanoGenizer can be widely used in the pharmaceutical, biochemical, cosmetics, food and dairy industries among others. It can also support experimentations from particle size reduction to cell disruption, nano emulsions, nano dispersions, liposome and more.

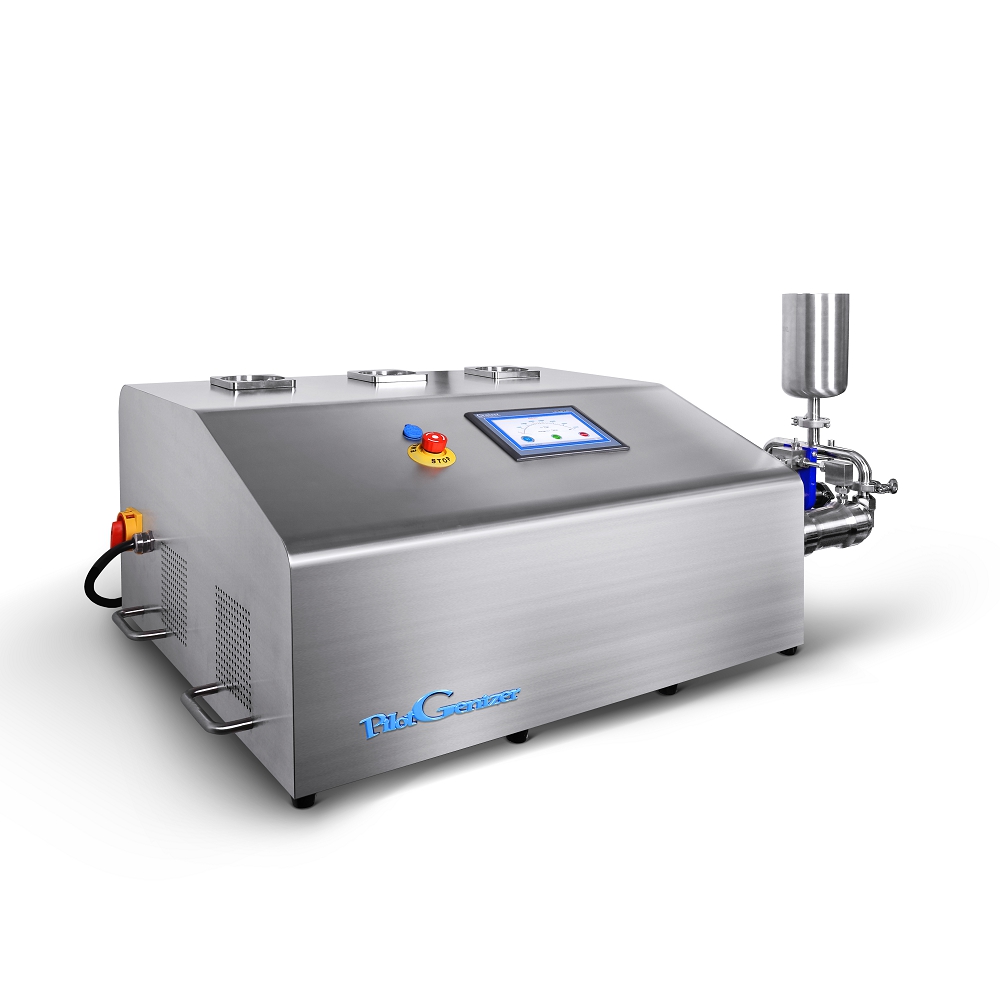

PilotGenizer Pilot-scale High Pressure Homogenizer from Genizer LLC

The PilotGenizer is a pilot-scale ultra-high-pressure homogenizer and cell disruptor from Genizer LLC. It is electric-driven and gives formulation development experts more alternatives and capacities for cell disruption, emulsification and particle size reduction quickly and easily.

PilotGenizer dual pumps system is based on a digital control design and is simple to use, with an auxiliary diamond chamber that helps pre-mix the sample and aids the nano-sizing procedure, as well as a primary diamond interaction chamber that disrupts the cell and reduces particle size. In the sample cooling unit, a 316 L stainless heat exchanger is employed to help cool the samples.

Genizer PLC touch screen provides operators with multi-advanced features, such as auto-stop configuration (cycle numbers, set time and pressure) and precision sampling. 316 L stainless steel, 17-4 ph stainless steel, titanium alloy, tungsten carbide, PTFE, UHMWPE, or other corrosion-resistant materials are used on any parts that come into contact with the medium.

Main Features of the NanoGenizer:

- Diamond interaction chamber technology

- Flow rate: ~20 L/H at 30, 000 psi (water value)

- Pressure: 25,000 psi, 30,000 psi and 45,000 psi

- Sanitary dual pumps system

- Control system: PLC touch screen, digital pressure value, auto-stop configurationMinimum

- Application: Nano emulsions, liposomes, fat emulsions, nano dispersion, cell disruption, deagglomeration, graphene, and carbon nanotube

Use the Mini Hand Homogenizer for Small Biochemical Projects

Compared to pneumatic or hydraulic liquid processors, the HandGenizer is an eco- and budget-friendly mini homogenizer. It is a manual high pressure homogenizer that works by shifting the pump handle up and down. It needs no PLC control system or electricity and is perfect for basic experimental tasks, particularly when handling small quantities of liquid samples.

The HandGenizer’s mini pump has been designed specifically to provide the preferred pressure to the product stream. When the pump handle is lifted, a small quantity of the sample will be pulled into the mini-pump body. By shifting the pump handle fully down to make a high-pressure profile (maximum 30,000 psi) to the sample stream, this portion of the sample will enter the check valve and the Genizer Y-Type diamond interaction chamber. Finally, it exits the outlet to be collected.

It can also combine with a Genizer online liposome extruder to achieve liposome down-sizing.

Main Features of the NanoGenizer:

- Diamond interaction chamber

- Pressure ranges up to 30,000 psi

- Capacity: 10 to 30 ml/min@ 30, 000 psi

- Power: Manual operations

- Minimum sample volume: 2 ml

- Spares and tools

- Application: Nano emulsions and liposome

Genizer Lipid Extrusion Methods

Liposomes have grown as an important biomedical carrier system. One of the most critical factors influencing the performance of liposome is particle size. High-pressure homogenization, extrusion and sonication are methods for reducing liposome size. The extrusion technique is a reasonably mild and quick procedure among them.

Genizer liposome extrusion line includes jacketed liposome extruders, online and hand driven liposome extruders

Genizer Online Liposome Extruders:

The Genizer Online Extruder combines with a high pressure homogenizer, which can help decrease the number of passes required to attain a perfect liposome size distribution and desired particle sizes since the homogenizer system (diamond interaction chamber) will help pre-treat the liposome sample to the nanoscale.

Features:

- Capacity of the extruder barrel: 25/200/1000mL, 8/20L

- Cooling: jacketed thermo barrel

- Material: 316L stainless steel, NBR or Viton

- Spares: O-rings, collection silicone tubing

- Including: Large pore support screen, laser micro pore disc

Genizer Hand Driven Liposome Extruders (Mini scale):

The Genizer HandExtruder is a low-cost micro liposome extrusion tool. Two gas-tight syringes, an extrusion body and a stabilizing block are included.

It facilitates liposome preparation with hands-on operation. The user can gradually push the plunger of the filled syringe to drive the sample through the filter membrane within the extruder body, and then gently push the plunger to return the sample to the original syringe. To get a sample with uniform liposome sizes, the user can repeat these two steps five to ten times.

Features:

- Catalog No: HandExtruder — 1 mL; HandExtruder — 2.5 mL

- Cooling: jacketed thermo barrel

- Mini sample size: 0.25 mL

- Spares: O-rings

- Feed and Collection: Gas-tight syringe, Hamilton

Genizer Diamond Interaction Chamber Technology

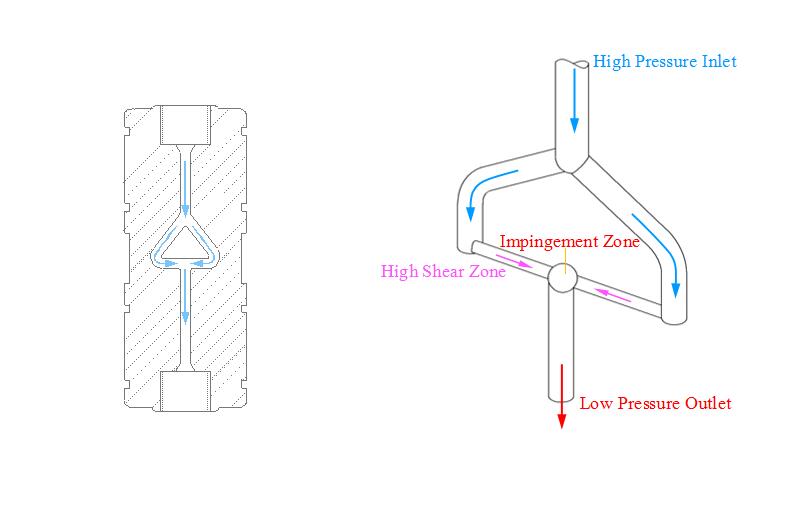

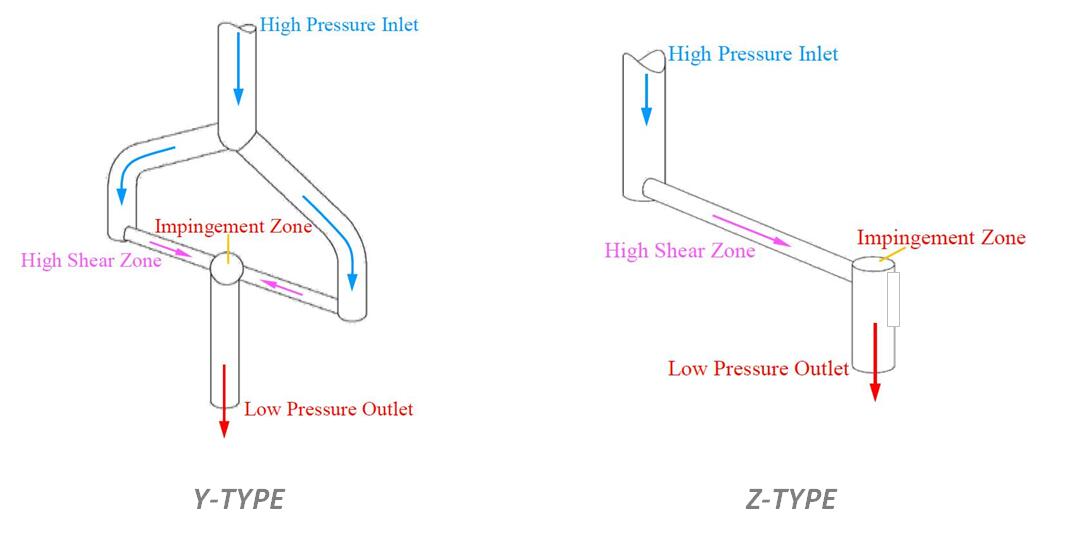

The Genizer diamond interaction chamber is the key component of Genizer high-pressure homogenizers. It makes use of microfluidic technology, and the inside has been provided with nano-size micro-channels. Here, the user's formulation is exposed to forces of strong impact and high shear, thereby leading to nano cell disruption and nano-article dispersion.

It has Y-Type and Z-type for different applications. The Y-type interaction chamber, is regarded as one of the most powerful homogenization chambers to date. In this system, the flow stream is split into two channels that are redirected over the same plane at right angles and propelled into a single flow stream. High pressure promotes a high speed at the crossover of the two flows, which results in high shear, turbulence, and cavitations over the single outbound flow stream.

The Y-type interaction chamber is widely used in the preparation of pharmaceutical emulsions because it minimizes cavitation and produces exquisite, stable particle size and PDI (poly dispersity index) control ability. Genizer and Microfluidics Corp. are the main manufacturers of the diamond interaction chamber. At present, the Y-type diamond interaction chamber is mainly used in high-end nanotechnology, and it occupies more than 90% of the US pharmaceutical industry. Genizer’s temperature-controlled interaction chamber avoids temperature surges and enables working pressure of up to 60,000 psi.

Generally speaking, the Y-type is more suitable for the treatment of liquid-liquid materials, and Z type is for the treatment of solid-liquid materials.

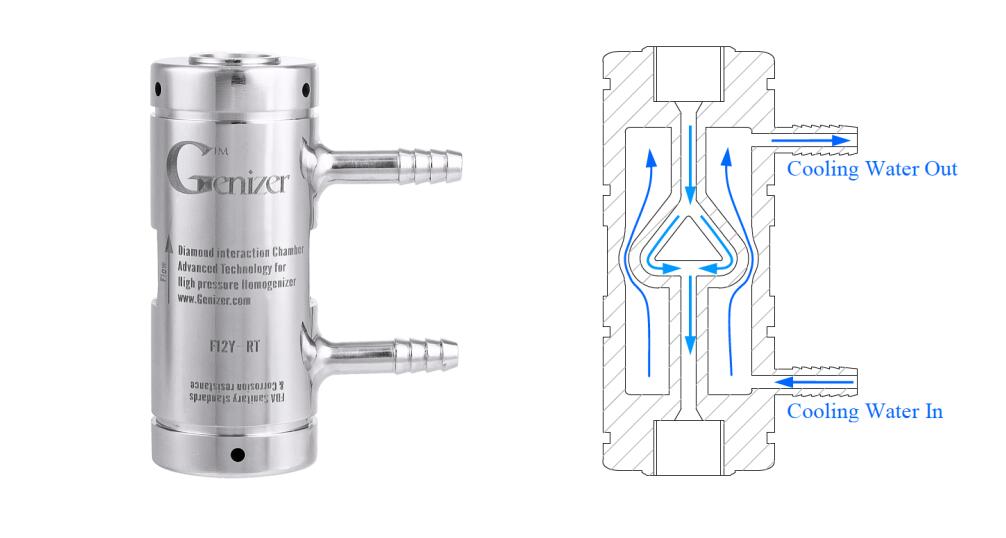

Cooling Options:

The traditional method cools the chamber by immersing entirely in the cooling bath, but the chamber's thick steel cover makes this an ineffective solution. Genizer's patent fabrication has the cooling option inside the chamber, which allows for much more effective heat exchange.

Popular Models:

Y-Type: F12Y, F20Y, N40Y, J30Y, F30Y, F20Y-12

Z-Type: G10Z, H10Z, H30Z, H230Z, L10Z

Genizer Jacketed Liposome Extruders:

The Genizer Jacketed Liposome Extruder utilizes a nitrogen gas cylinder to force a drug, protein or gene liposome suspension via a track-etched membrane with a predetermined pore size; generally, 5–10 passes are enough to create a sample with consistent liposome size. The Genizer Jacketed Liposome Extruders are designed to produce uniform unilamellar liposomes and lipopolyplexes with minimal dead volume.

Features:

- Capacity of the extruder barrel: 10/100/800/3000mL

- Cooling: jacketed thermo barrel

- Material: 316L stainless steel, NBR or Viton

- Spares: O-rings, collection silicone tubing

- Including: Large pore support screen, laser micro pore disc, high pressure nitrogen tubing G5/8